Wotton-Under-Edge

Acoustic upgrade of existing shop into flats

General Construction Notes:

- Follow the manufacturer’s instructions carefully

- Stagger & tape all junctions on plasterboard linings

- Around the perimeter of plasterboard linings leave a 5mm gap & fully fill with acoustic sealant

- Mineral wool in cavities must cover the entire area with no gaps or sagging

- Resilient bars must be installed correctly, use appropriate screw lengths, do not screw through the plasterboard into the timbers behind

- Do not crush the resilient bars

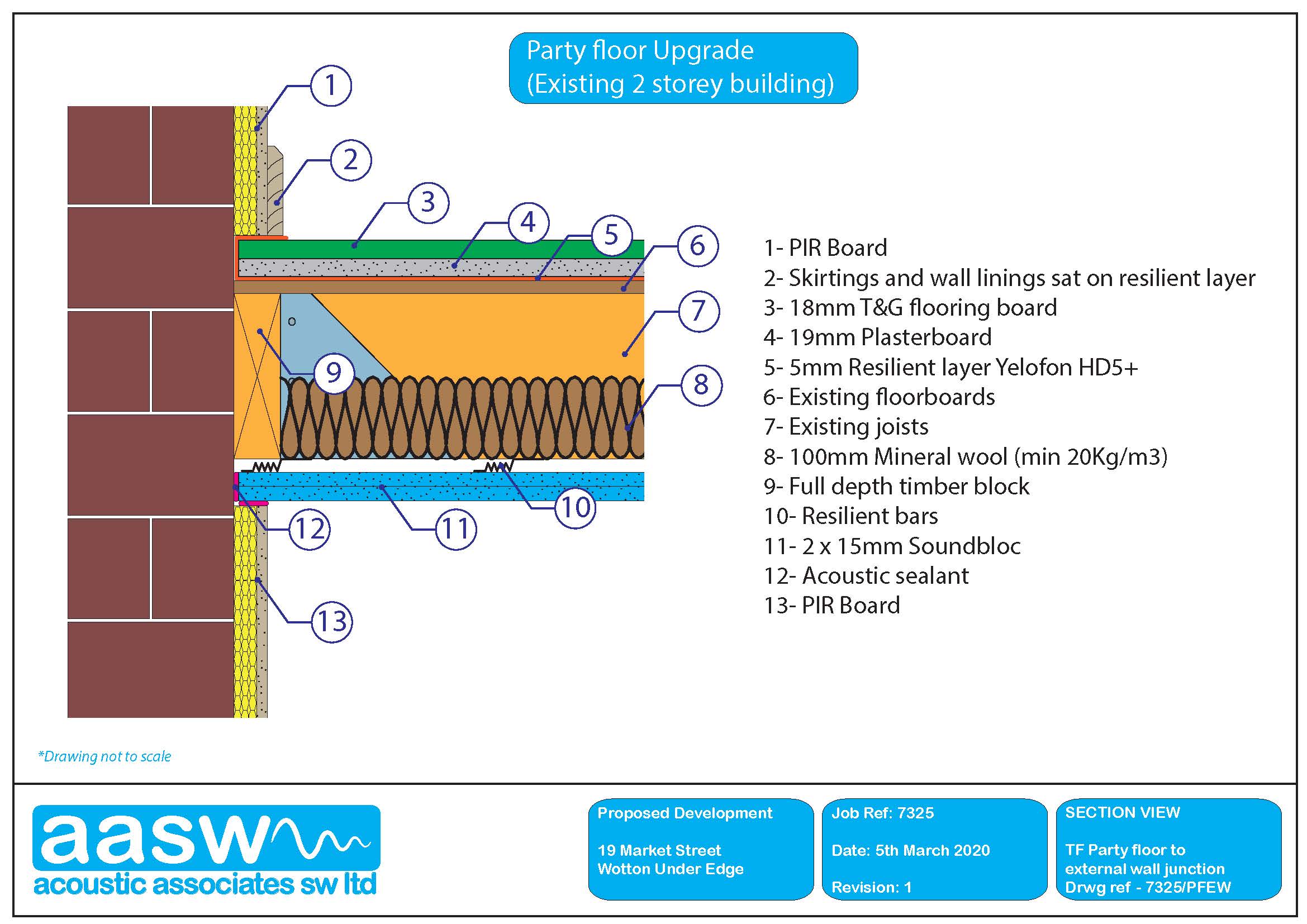

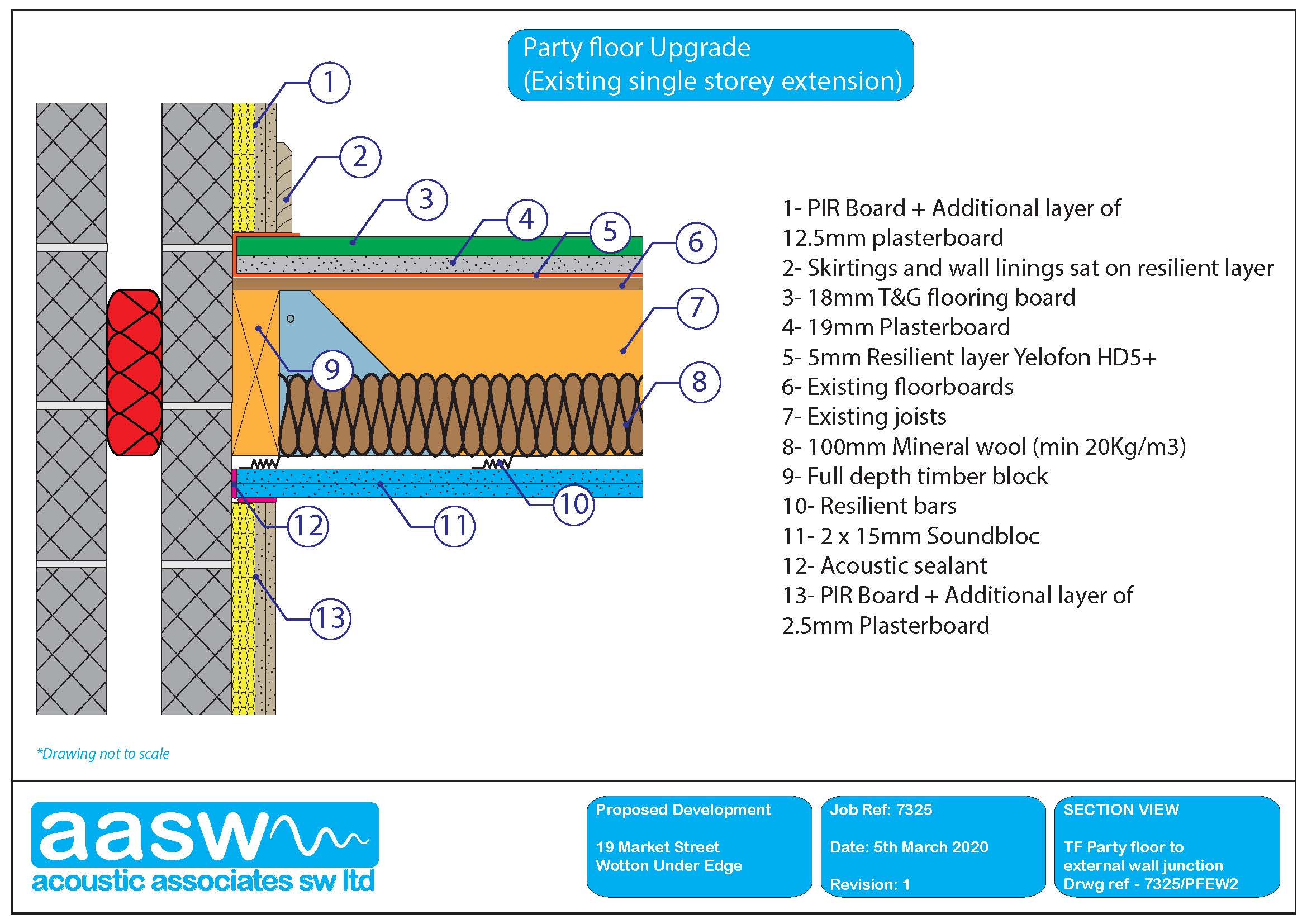

- Lay the resilient layer over the entire floor area & lap up the walls by at least 70mm

- Spot bond the 18mm T&G flooring to the 19mm plasterboard plank, these layers must remain free floating on the resilient layer

- Lay the resilient layer back down on the walking surface, 18mm T&G; capture with skirtings & cut flush

- Full depth timber blocking is required around the perimeter of all timber joisted floors

- Attention to detail and high-quality workmanship will be required throughout the build if a good acoustic performance is to be achieved

Service Void Penetrations:

- There should be no service void penetrations through party walls

- Sockets on party walls must be staggered and not set out back to back

- SVP’s through the party floor should be carefully cut out, the pipes wrapped with 25mm of mineral wool and boxed inside 2 layers of 12.5mm plasterboard. The boxing & plasterboard must not touch the pipes inside

- If recessed lights are to be installed into the ceilings, they must be fire & acoustic rated

Steels:

- All steels must be treated like SVP’s, wrap the steel with 25mm of mineral wool and box inside 2 layers of 12.5mm plasterboard

Contact Us

We welcome any enquiry - small or large.

01452 619871

07718 793967

cellartechsouthwest@gmail.com

The Black Containers, Rear of Bullens Manor Farm, High Street, Upton St Leonards, Gloucester GL4 8DL